COIL TUBING

INDUSTRY-LEADING COIL TUBING SERVICES ACROSS WESTERN CANADA

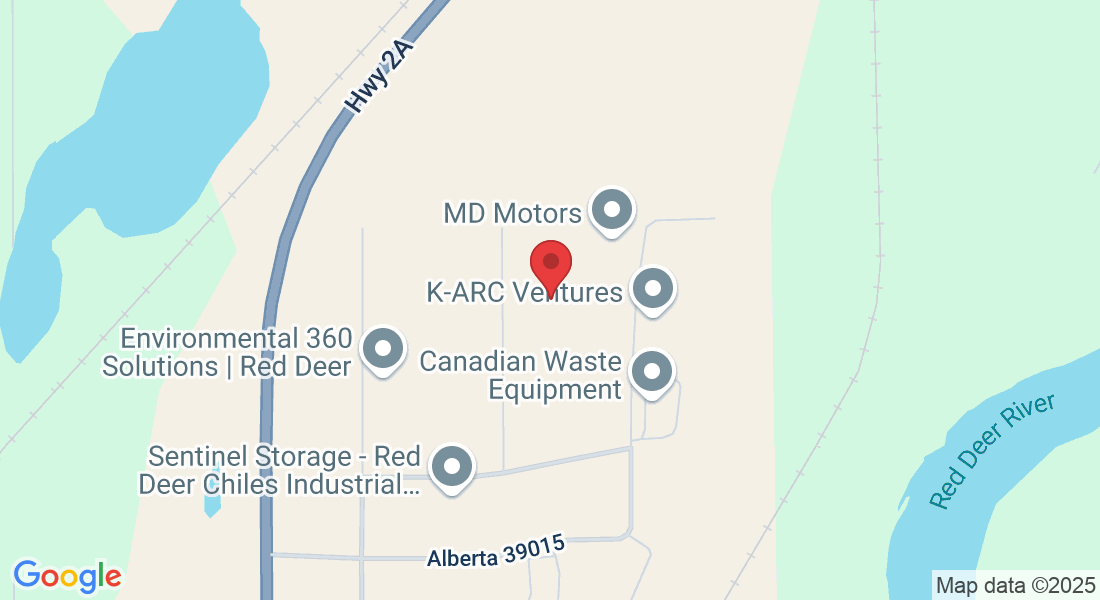

TAZ Well Servicing provides professional, IRP-compliant coil tubing services across the Western Canadian Sedimentary Basin. With a modern fleet of 40K, 80K, and 120K coil units, we support everything from shallow gas wells to deep horizontal completions — including up to 6,500 metres of 60.3 mm (2 3/8”) coil.

Based in Alberta, we serve field operations across Western Canada with experienced crews, rapid mobilization, and a safety-first approach.

What We Do

TAZ Well Servicing offers expert coil tubing services for efficient well intervention and optimization. Our key capabilities include:

Wellbore Cleanouts – Remove sand, scale, and debris to restore flow and integrity

Coil Tubing Completions – Efficient horizontal and vertical well completions without the need for a workover rig

Confirmation Runs – Verify downhole conditions and tool placement with precision

Sleeve Shifting – Open and close sliding sleeves to activate zones for production or stimulation

Fishing Operations – Retrieve stuck tools, plugs, or coil safely and effectively

Plug and Port Milling – Post-frac plug and port removal using high-torque milling assemblies

Plug Setting & Retrieval – Set or recover bridge plugs and isolation tools with control and accuracy

More

Have questions? Give us a call, and our team will be ready to assist you.

DEEP COIL 120K

Capacity: 60.3mm (2 3/8″) - 6500m

This unit is ideal for horizontal completions, fracking, and production operations, as it meets contemporary equipment standards for outstanding performance.

INTERMEDIATE COIL UNITS 80K

Capacity: 38.1mm (1.50”) 5000m

44.5mm (1.75”) 4500m

50.8mm (2.0”) 4000m

Specially developed for all types of work including Class III wells. These units include a support unit equipped with a 45 or 50-ton picker to hold injector.

SHALLOW COIL UNITS 40K

Capacity: 31.8mm (1.25") 3000m

38.1mm (1.50”) 2500m

44.5mm (1.75”) 1750m

These units are self sufficient with pickers, air compressors, soap dispensers and specialize in Shallow gas and ABD wells.

Coil or Nitrogen, we’re ready when you are.

Frequently Asked Questions

What is coil tubing used for in oil and gas operations?

Coil tubing is used for well interventions, cleanouts, acidizing, fluid pumping, nitrogen lifting, and mechanical operations like milling or plug setting. Its flexibility and continuous design make it ideal for reducing downtime and improving efficiency in both producing and non-producing wells.

How does coil tubing work in well servicing?

Coil tubing works by inserting a long, continuous steel pipe into the wellbore while pressure is maintained. It's pushed into or pulled out of the well using an injector head. This setup allows for real-time interventions, chemical treatments, and mechanical actions without removing production equipment.

What are the main advantages of coil tubing services?

Mandatory safety training includes: H₂S Alive (Hydrogen Sulfide Awareness), first Aid/CPR, WHMIS (Workplace Hazardous Materials), TDG (Transportation of Dangerous Goods) and CSTS (Construction Safety Training System) Additional training like fall protection or confined space entry may be required based on the role.